We are a family business based in Wickede (Ruhr). We have been manufacturing flexible paper packaging for more than 130 years. We permanently adapt our products and services to the market conditions.

We have been BRC hygiene-certified for many years and, under these conditions, we manufacture high-quality and contemporary packaging, primarily from paper and - where sensible and necessary - from material composites.

Our customers all over Europe appreciate our quality, reliability and top service. And of course our innovative ideas that help to market their products successfully.

We supply packaging for manual, semi-automatic and fully automatic processing. Our "automatic bags" are a guarantee for high machine availability. We bag makers are a team of about 200 employees, including 17 apprentices and 2 dual students. We develop and manufacture innovative packaging with passion and skill.

The development of attractive, contemporary and resource-saving packaging solutions, state-of-the-art machinery and, of course, the training and further education of our employees are the central pillars of our activities.

We are convinced that sustainable packaging solutions make the world a little better!

WEBER Verpackungen is a team of qualified, creative and experienced minds. Graphic designers, packaging technologists, engineers, business people and many other specialists work on innovative and customised packaging solutions every day. And we always have the goal clearly in mind: the success and satisfaction of our customers. And satisfied customers require qualified and satisfied employees. At least, that's how we see it. The training and further education of our employees therefore remains a central pillar of our corporate philosophy.

Discover your new job in our career portal now and become part of the bag makers

We develop attractive, contemporary and resource-saving packaging solutions by using the latest technologies, innovative ideas from our technical development department and our qualified specialists.

With us, you benefit from the following advantages & services:

From professional advice and high-quality products to punctual and reliable delivery.

We focus on your needs and use your feedback to constantly improve ourselves and the way we work.

Only the highest quality raw materials and the latest processing techniques, as well as compliance with high legal standards and self-imposed demands, ensure the quality of our packaging and thus also your satisfaction. This high quality standard also includes consistent implementation of all hygiene procedural rules in our modern food packaging production plant.

You can rely on hygienically and qualitatively flawless products, punctual as well as reliable deliveries and, of course, our innovative and sustainable ideas that turn your products into sales hits in our packaging.

We are constantly working to put new technologies and innovative ideas from employees and customers into practice through our own technical development department and our qualified specialists. This results in individual and beneficial new packaging solutions for our customers and the end consumer. Together, we have the courage and energy to implement innovative ideas and redesign existing processes!

We can design, print and produce almost any of our products completely according to your wishes. We offer you complete system solutions that are geared to your requirements and expectations and are constantly updated.

We are active in many industries and are therefore not limited to one standard. Almost any shape and print is possible. In addition, we offer many different extras for our products and thus design unique packaging for you that always shows your products from their best side.

Graphic designers, packaging technologists, engineers, business people and many other specialists work together for you on innovative and customised packaging solutions.

Our goal: the success and satisfaction of our customers. This requires qualified and satisfied employees. The training and further education of our employees and the appreciation and respect for the contribution of each team member therefore remains a central pillar of our corporate philosophy.

Our goal is to secure the future viability of our company in the long term while at the same time meeting ecological and social demands.

We apply the term sustainability not only to the development of resource-saving packaging solutions, but to all our corporate decisions. To this end, we take into account economic, social and ecological aspects. We strive for a sustainable development of WEBER and assume social responsibility. For us, there is no alternative to sustainable action, because we want to make a contribution to an intact environment and society for our next generation of bag makers.

Our certifications are only the official proof of our comprehensive hygiene management, our sustainable actions and our moral as well as ethical principles, but above all we act responsibly out of conviction.

The aim of our hygiene policy is to avoid any form of contamination of our products (physical/ chemical/ biological or allergenic origin). With safe and legally compliant products and the BRC GLOBAL STANDARD as a basis, we thus realise comprehensive consumer protection.

The certifications according to FSC® (FSC®-C105659), PEFC (PEFC/04-31-2160) and DER BLAUE ENGEL illustrate our sustainable corporate policy and the high value that the resource-saving handling of raw materials has for us as a manufacturing company.

As a SEDEX member and with the UPU Code of Conduct, we ensure compliance with global requirements for ethical and moral action and help to improve responsible business practices in global supply chains.

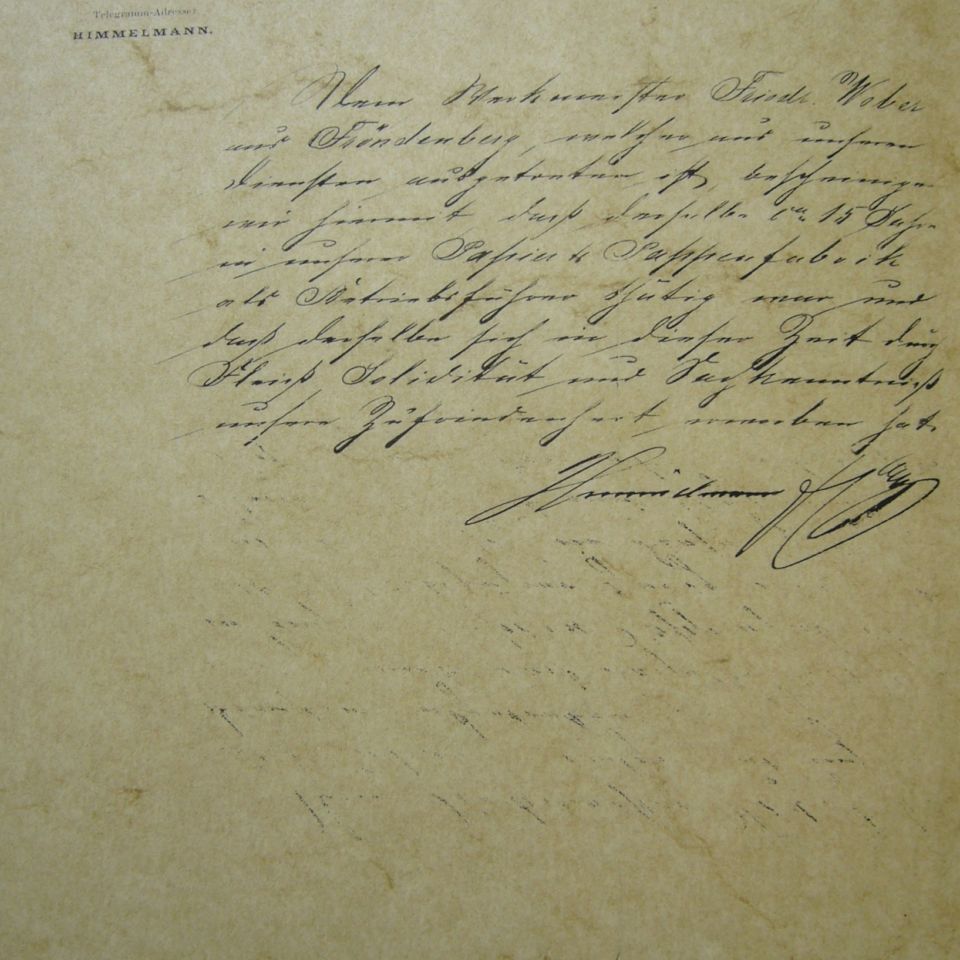

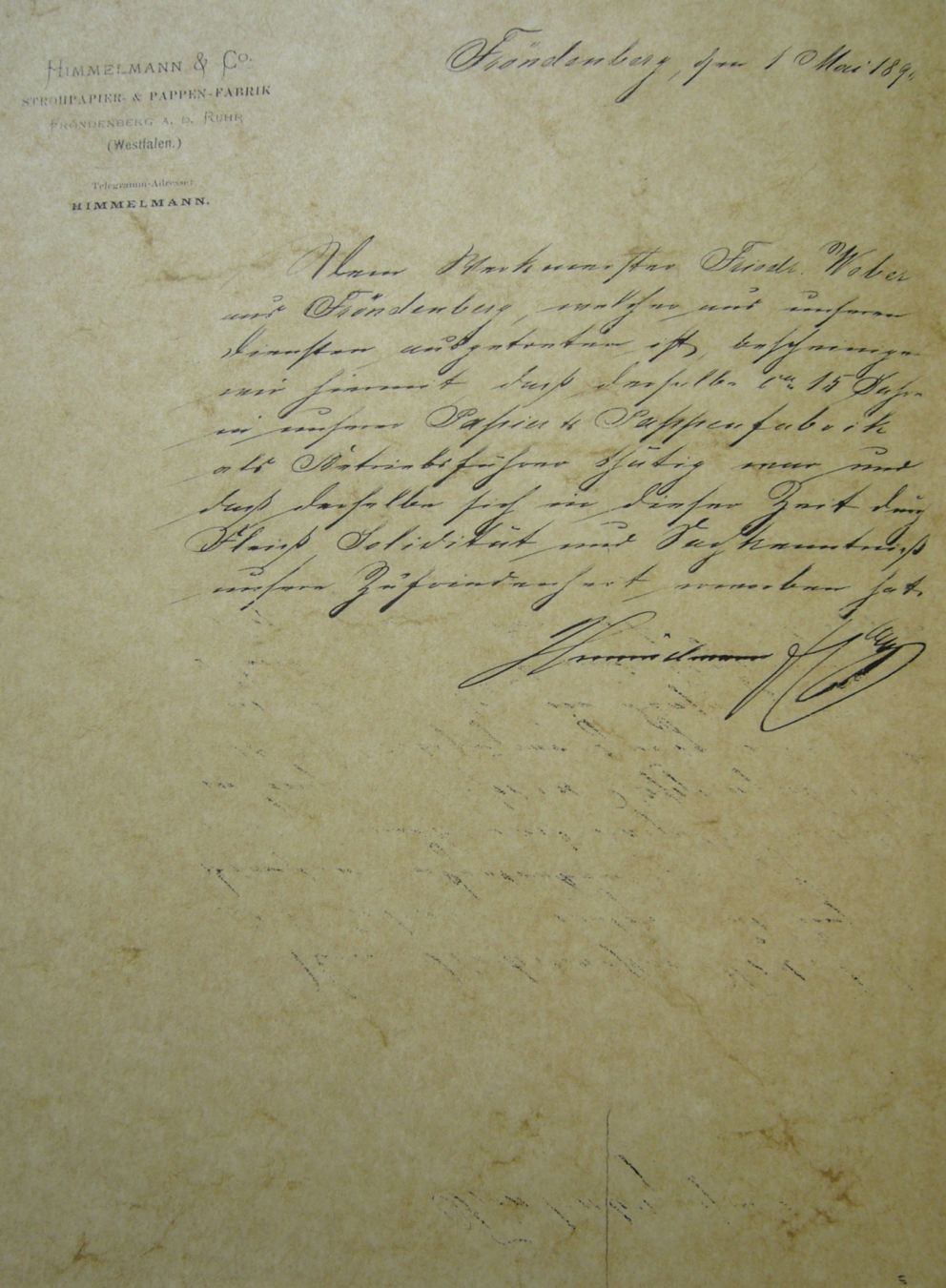

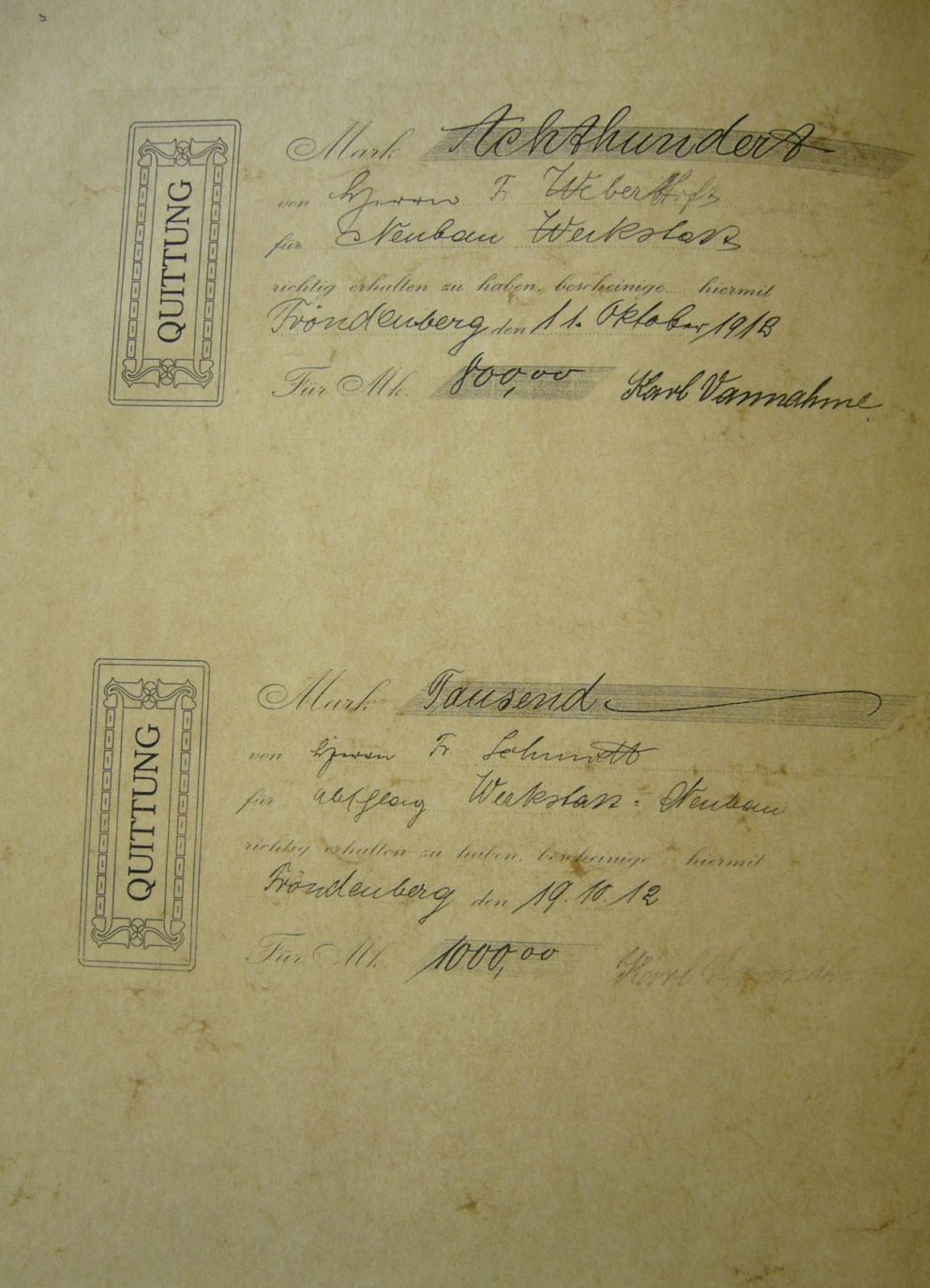

The history of WEBER Verpackungen

Part-time employees, including schoolchildren, glued bags and pouches by hand. The attic of a goat shed in Fröndenberg served as the first "company building".

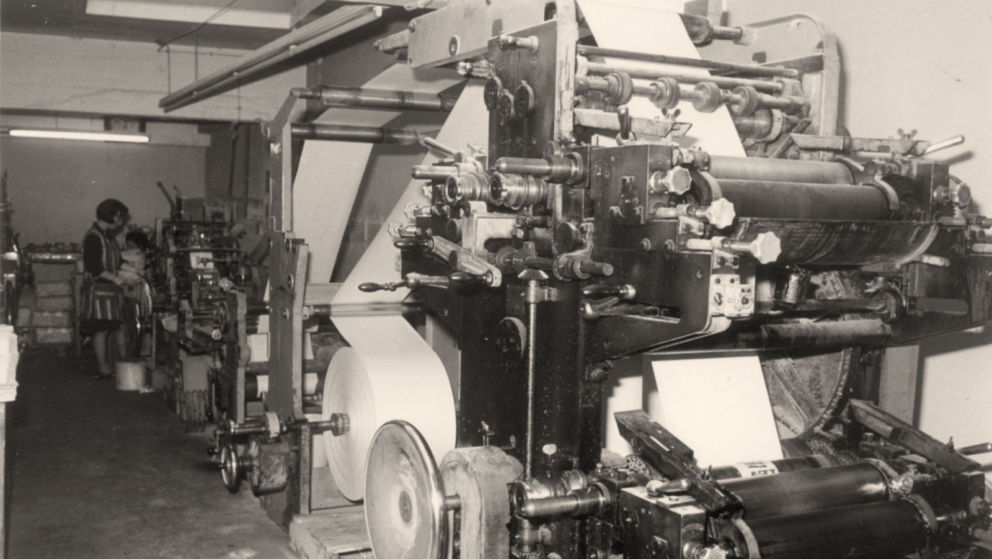

Expansion, modernisation and rationalisation of production. Pleated bags outstrip the other product groups.

Relocation to the new production facility in Wickede (Ruhr) and further modernisation of production technology. 42 employees.

Foundation of the company by Friedrich Weber.

Part-time employees, including schoolchildren, glued bags and pouches by hand. The attic of a goat shed in Fröndenberg served as the first "company building".

Erweiterung und Technisierung der Produktion durch Beutel- und Spitztütenmaschinen

Expansion and mechanisation of production with bag and tapered bag machines.

The company is relocated to the outskirts of the town. 30 employees.

Expansion, modernisation and rationalisation of production. Pleated bags outstrip the other product groups.

Relocation to the new production facility in Wickede (Ruhr) and further modernisation of production technology. 42 employees.

Enlargement of the production facility by one third. 120 employees.

Expansion planning. 180 employees.

Extension of production and storage hall.

Commissioning of a high-end flexographic printing system with 10 colours.

Commissioning of Technikum

130th company anniversary. 202 employees.

Commissioning of a further high-end flexo printing line.

Presentation of the first self-developed packaging machine

Let your imagination run wild and send us your ideas - we will be happy to advise you! Prices and minimum quantities are available on request. Just give us a call or send us an e-mail.

T +49 2377 80 99-0

info@weberverpackungen.de

For applications, please use karriere@weberverpackungen.de or our career portal.

Unfortunately, applications sent to us via info@weberverpackungen.de cannot be processed.

By submitting this form, you agree to our privacy policy and agree, among other things, that the data you provide will be stored and processed electronically.

Here you can find our imprint and our privacy policy.